Developed over two years of working with retailers, BACTRAC is set to fill a gap for IT in reverse logistics that caters specifically for the needs of the UK and European market.

The first logistics software to be designed by a UK logistics service provider, it is launched at a time when there is concern amongst businesses about how to handle returns, ahead of the EU Directive on WEEE (waste electrical and electronic equipment), which comes into effect in August 2004. It addresses the challenge of growing returns faced by retailers in the UK, estimated to cost the sector £500 million each year.

BACTRAC has been developed by Christian Salvesen to help UK and European businesses manage the process of dealing with the goods customers bring back.

Following years’ of work with retailers such as IKEA, House of Fraser and Marks & Spencer on reverse logistics, BACTRAC sets out to fill a specific gap for reverse logistics software. Unlike the US, where over 90 per cent of returns go straight back to the manufacturer; in the UK and Europe returns handling is much more complex as each must be dealt with according to individual agreements with suppliers and environmental legislation.

Based on COMET (Salvesen’s track and trace system for pallets, trays and other in-transit packaging), BACTRAC is custom-built for each customer to deal with returns on an item by item basis. Configured around the products the retailer sells, BACTRAC can ask specific questions in line with agreements with the supplier.

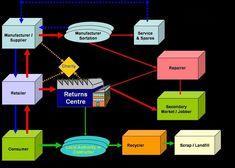

Based on the answers, BACTRAC decides the most cost-effective way to deal with them. That may be reselling in store, sending back to the supplier, dismantling for parts, reselling to secondary markets or auctioneers, or scrapping according to legal requirements such as WEEE.

Currently, without adequate systems in place, Cranfield University estimates British retailers lose £200m per year. This is expected to increase with the EU Directive on WEEE. As part of an EU drive to recycle two-thirds of all waste by 2016, it reduces the proportion of end-of-life household electrical items that can be disposed of in landfill from nine in 10 to one in three overnight. It shifts the onus onto ‘producers’ - sellers, distributors and makers to put alternative arrangements for recycling and reuse in place.

Based on bar-code scanning, BACTRAC is initiated in store as the customer brings goods back for credit. In the warehouse, workers scan returns into BACTRAC and answer a series of questions based on the condition and supplier agreement. Using ‘inheritance techniques’ to speed up the process, these are arranged so that decisions are made as early as possible.

Where the item should be reworked, BACTRAC sends it for PAT testing. Where there is a returns agreement, BACTRAC controls labelling and pallet building. Where there is no returns agreement BACTRAC directs into secondary channels for reselling.

To help customers cut and recover the costs of processing returns, BACTRAC is integrated with customers’ own SAP and ERP and Salvesen’s SHARPNet and ULTIMA systems and can give customers information about the progress of returns online.

By giving buyers information about volumes and the value of goods that come back by product, store and supplier, it means buyers can negotiate prices that reflect the costs of returns with suppliers. By generating reports on performance against KPIs (key performance indicators), operations managers can monitor performance by employee and over time against KPIs eg items processed each week. Incorporating features that mean BACTRAC can be scaled up and down, customers only pay for features that are useful.

Brian Gaunt, UK managing director, Christian Salvesen, commented: “There is growing pressure on all retailers to deal with goods coming back through the supply chain, as the volume of returns rises and environmental legislation dictates how they must be dealt with. BACTRAC is a pioneering concept for reverse logistics and gives businesses a real alternative to traditional reverse logistics systems. It comes at a critical time when many businesses in the UK are looking at how they can protect themselves from the growing cost of returns and deal with them to compete on price.”

BACTRAC is the latest in a suite of award-winning IT systems developed by Christian Salvesen’s in-house team of 100 specialists. These include the SHARPNet and COMET track and trace and ULTIMA warehouse management systems. Supporting Christian Salvesen’s dedicated and shared-user networks, IT is distinguishing Salvesen on its ability to provide supply chain solutions that are custom-built to suit individual contract needs.

SELECTING A PARTNER

For those following this mini series then, as I have suggested before, you will have identified your business needs; they have been agreed with your management team and a cross section of affected end-users. You are now ready to begin the selection process.

A key part of this will be the selection of an implementation partner. To set this in context, it is necessary to understand how business management solutions are brought to market by the IT industry.

The IT business management marketplace is very fragmented in the UK with more than 100 vendors competing for market share. Industry experts predict that consolidation will reduce this to single figures over the next three years.

Suppliers operate direct, indirect and a mixture of both models as a means of taking their products to market. The direct model is the easy one to understand i.e. you are dealing directly with the software authors. In the indirect and mixed model, you are likely to encounter implementation partners working with the software authors.

In the direct model where you are dealing with the product authors, you may have the advantage of influencing their future functionality. However, this could be offset by the fact that they may be on the small side and therefore at risk from the industry consolidation.

The indirect model is where authors have traditionally appointed authorised implementation specialists. Here you are not only likely to have a choice of partners from which to choose but arguably a much more solid product.

The common mistake made by purchasers in the past has been to assume that all system centres operate to the same standards. The reality is that skill profiles vary enormously among reseller channels. Following a few basic guidelines would assist in weeding out what may at first impressions seem like a suitable implementation partner.

The first priority should be to carry out the basic “hygiene” checks on a potential partner. This includes financial stability, expertise in the field of finance and business operations solutions, company reputation and any relevant industry accreditations. Few medium-sized companies have the time and resources to carry out a full scale evaluation of all possible supply source options. The following may provide some useful indicators in the assessment process.

On the financial front, a quick search on the company’s house website www.companieshouse.gov.uk will tell you when they last filed their accounts. For a £5 fee, you can download their latest report and accounts and annual return. While this is no guarantee of future financial stability, it will at least give you a useful insight into their trading history, balance sheet and current share ownership.

The approach taken to your enquiry is also a useful indicator. Professional business management solution providers try to understand the culture, business issues and barriers to growth of any company they plan to work with. Expect some probing questions on this aspect of the approach. Be concerned if this is curtailed to get to the demonstration.

Ask to see documented evidence of their implementation process. Professional companies will have detailed scoping procedures, deployment planning aids and monitoring procedures. Get the potential supplier to define who is likely to be responsible for your installation and try to meet some of the people. Establish whether they are full-time employees of the potential supply partner or self employed consultants.

Demand customer references but be thorough in your questioning. Ask how the company reacted when things went wrong. Were the implementation procedures followed and how well did they work? Who were the consultants working on the project and how effectively did they liaise with end users? What was the quality of the end-user training? Was the project implemented to timescales and to budget? If not, why not? If you were to do it again, how would you improve the way in which it was handled?

In the next article, I will be looking at the importance of a reliable and secure infrastructure platform for your business management system. For further information email me on bobr@angliabc.co.uk

WONDERS OF THE WEBSITE

Journal readers who aren’t internet enthusiasts are probably heartily sick of being told to create or improve their website. But it’s good advice. Trading without a website is the same as not being in Yellow Pages. Conversely, a well thought-out website can definitely be a business builder.

The key virtue of a website is that it can communicate a large amount of information at low cost. Especially if you aim to sell over the web it’s an opportunity to list all your stock. Alternatively, for a smaller retailer if you want to drive footfall at your store you can focus on special offers, new products, industry issues and, critically, your expertise and enthusiasm.

Above all, use it to sell your areas of specialisation. The web has no geographical boundaries - you can sell to anyone, anywhere. There are five key dos and don’ts for web marketing for the small business.

• make your site easy to navigate; if people can’t find what they want, click, you’re history.

• keep your site current; dated website content is unforgiveable because updating is easy and customers expect latest information on a website.

• make the tone and content appropriate to your customers; people don’t turn into teenage uber-nerds just because they’ve got a computer mouse in their hand.

• make your site interesting but fast-running; this is tricky because the features that create interest (pictures and video) slow it down, but it’s an important balancing act.

• the bit that most businesses forget, publicise that website address. One coloured cards to hand out in the store, stickers on product, big and bold on store-front, delivery van, signage, stationery, advertising - everywhere!

KETTLE ON BOIL WITH TROPOS

Major fresh vegetable supplier Kettle Produce has picked SSI’s TROPOS ERP suite to underpin a changing business model.

Kettle is replacing its existing computer system and associated standalone spreadsheets and paper-based systems.

With turnover topping £60 million a year, the privately owned company supplies the leading supermarkets with fresh vegetable products - especially greens, root vegetables and prepared mixtures - from its sites at Balmalcolm and Orkie, in Fife.

Established in the 1970s by two local farming families to distribute vegetables, Kettle Produce has moved significantly into manufacturing. In addition to its traditional washing, trimming and packing operations it has a high care preparation area producing ready to cook packs which combine several products. This area has grown significantly in recent years.

It is implementing a full range of TROPOS modules, covering supply chain, quality management, online traceability and customer relationship management. The fully integrated solution also includes Coda Financials, Cognos Impromptu and shop-floor data capture capabilities. SSI is also producing a special interface to the Muddy Boots field management system which records data relating to crops grown for Kettle Produce.

As a supplier to the major supermarkets, Kettle Produce receives orders daily - mostly through electronic document interchange (EDI) - and it delivers to regional distribution centres seven days a week. In this fast-moving environment, an integrated system is needed to ensure that orders are fulfilled promptly, correctly and without waste.

Liz Waugh, financial director of Kettle Produce, says: “At the moment, we have disjointed information because of the combination of our main system, spreadsheets and paper based systems throughout the business. We are looking to improve efficiency by streamlining the process. The time was right for a review of the complete business system and processes, and that’s why we went to the market to look at various suppliers, including SSI.”

Trevor Lewis, managing director of SSI, says: “Kettle Produce represents one of the widest TROPOS applications in our expanding food industry customer base, with involvement literally from field to supermarket shelf. Our solution provides a comprehensive production, logistics and financial management capability to support ongoing business and further development.

“This application demonstrates the flexibility of TROPOS and the possibilities for integration with other software in the food industry and other sectors.”

Anticipated benefits of the SSI solution, due to go live at Kettle Produce later this year, include a dramatic reduction in paperwork, and improved availability of operational and financial information. Management will have a clearer picture of the entire operation. More accurate production planning will give greater visibility to discrepancies of supply and demand.

Waugh says: “What we expect to get out of the project is a far more efficient business system which will provide management with more accurate and quicker information on processes. This is very important when you are dealing with perishable products like vegetables. We anticipate becoming much more efficient simply because it will be so much easier to manage information when it is all held in a central system.”

SSI specialises in the implementation and lifecycle support of web-optimised manufacturing and supply chain solutions for the process industries and ‘lean’ discrete manufacturers. Its TROPOS ERP solution, is used by many companies in the food and drink, chemicals, pharmaceuticals and mill-based manufacturing sectors, including Adams Pork Products, Gala Coffee & Tea, Giles Foods, Axminster Carpets, G&J Greenall, Pfizer, Rangemaster, Saxbys, St Ivel, Sundora, Tullis Russell, Turtle Wax, UCB and CWV (formerly Vymura). Recent wins include Fox’s Confectionery, Petrochem Carless and James T Blakemans.

SSI came to market in 2000 via a reverse takeover of the AIM-quoted Chelford Group.

No comments yet