In the packhouse, improving sorting efficiency is a tricky proposition. With a cascade of supermarket-bound produce passing through at high speeds, the stakes are as high as the volumes. New sorting machinery needs to combine speed, accuracy and labour reductions in a bid to beat shrinking margins.

Amid rising labour costs and downward price pressures, machinery can provide relief with even small improvements. “Minimum wage rises and Brexit are making it harder for producers; they want faster machines that are more reliable, with less footprint,” says Andy Beal, managing director of Gainsborough Industrial Controls. But with robot arms, advanced optics, and self-diagnosing machinery, suppliers are increasingly able to grade and sort their produce with ease and accuracy.

Lincolnshire-based Tong Engineering makes some huge lines. Its sorting line used by MH Poskitt handles over 1,000 tonnes of carrots every week. It integrates Swiss-made Visar optics to scan items on the conveyer, grading and profiling vegetables with robotic precision.

“By detecting crop defaults in a split-second, it allows customers to increase the volumes deemed fit for sale by at least five per cent compared to manual sorting – an impressive increase in a sector where small improvements can make a big difference,” says Edward Tong, managing director of Tong.

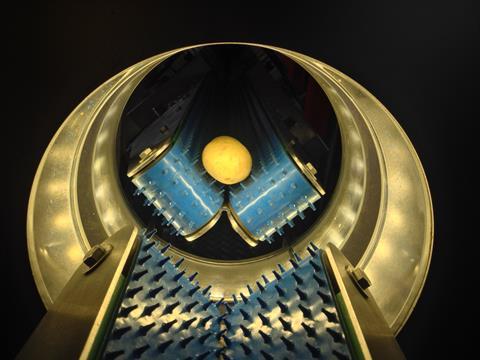

A global player in sorting equipment, Tomra touts its Spectrim sorter as the most advanced in the world. Spectrim snaps up to 500 high definition images of each piece of fruit that passes over the sorter, detecting hard-to-find external blemishes and delivering grading accuracy and consistency that packhouses need to ensure the highest return from their crop.

Once graded, the produce needs to be weighed, with errors in this department costing money and produce. “If you have 15 per cent giveaway per kilo, you’re adding too much and you’re not getting paid for that, so you’re losing money,” says Paul Bennion, managing director of machinery suppliers Xact. The Exact 100 is as tall as a bus and shifts 100 packs of citrus per minute. “It’s extremely gentle with the produce and easier to clean than most,” adds Bennion. “With the speed of it you just need one line, which reduces labour requirements and costs, in contrast to slower ones which might need two.”

With environmental concerns rapidly increasing, packaging has been thrown into the public spotlight. New machinery for packaging fresh produce has to be compatible with new, greener materials, but efficiency gains are also helping to cut back on waste for suppliers.

Ilapak and ULMA both offer ultrasonic bag sealing in their vertical fill machinery. The method can seal through any leaves caught in the seal area, reducing the rejection rate of products from an industry average of five to ten per cent to less than one per cent.

“All the major players have adopted ultrasonics and now the technology is starting to become more accessible to medium-sized players too,” notes Phil Rule, VFFS product manager at Ilapak UK.

Besides slashing leaky bag rates, ultrasonics is also green technology. It generates film savings of up to 20 per cent owing to a narrower seal area, and energy savings of up to 30 per cent compared to traditional heat seal technology.

Greater integration and smart machines that are “self-aware” are also raising efficiency in the packhouse. “Fresh produce is incredibly demanding as a packer. If the machine stops we know all about it,” says Beal. “Industry 4.0 in packaging means connecting things. GIC offers complete remote access, so we can deal with a machine and update software from the office. They can also run their own diagnostics so the machine can predict a breakdown.

“The latest developments are smart machines with total connectivity, so the manager can see what line is running, for different customers whether it’s Sainsbury’s, Marks & Spencer etc,” Beal adds.

In net packaging, Bennion says Spanish company Giro now offers a bagger with unrivalled flexibility and environmental credentials. “The latest machine can produce 10 different types of bag, all offering different styles. All use fully recyclable material.

“Quite often if you’re a machine manufacturer the link to the consumables is not really there. Giro makes the net, the film and develops the machines so it can integrate environmental factors across its design.”

Further innovations include the introduction of ozone into packaging by Scottish company Anacail, who recently agreed to exclusively supply Berry Gardens. Its machine puts ozone - which reduces the presence of yeasts and moulds - into already sealed packets to extend shelf life. Berry Gardens CEO, Jacqui Green, says: “This technology is game changing in our industry, using ozone, a proven sterilant, to reduce the presence of yeasts and moulds. This means extended shelf life, reduced waste and a better product for our consumer.”

In such an international industry Brexit will challenge UK suppliers and manufacturers, but Beal suggests companies will find a way. “The exchange rate of the euro could help us and as with food I think more companies are saying ‘tell you what, I think we should go British’.”

No comments yet