A new robot that will be able to move trays and boxes around glasshouses is being developed by the AHDB, University of Warwick, and several fresh produce businesses.

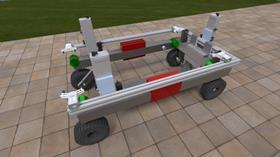

The new “autonomous guided vehicle” (AGV) is aiming to “transform the horticultural sector” by carrying out simple tasks, currently done by an increasingly scarce pool of seasonal labour.

Leading automation experts from the WMG, University of Warwick, are creating the model alongside three horticultural businesses: Crystal Heart Salad (lettuce propagators, Yorkshire), Valefresco (salads, Worcestershire), and WD Smith & Son (bedding plants, Essex).

It will have the potential to work in both glasshouse and outdoor environments to automate the movement of trays and boxes around the production area.

Grace Emeny, knowledge exchange manager at AHDB, said: “With the lack of available labour an increasing pressure for many businesses, there is a growing need to automate more routine tasks to enable staff to be reallocated to more skilled jobs.

“There are two main barriers that prevent the uptake of automation. Many off-the shelf solutions don’t work for diverse horticulture production systems and often the return on investment doesn’t stack up in the current trading climate. WMG were tasked with addressing both of these challenges, which we believe they are well on their way to achieving.”

Robert Harrison, professor of automation systems, WMG, University of Warwick said: “We’ve been able to apply the cutting-edge technology developed in the automotive industry to the challenging environment of horticultural production.

“We reviewed existing AGVs to ensure there wasn’t an available product that could meet the growers’ needs and have run a full analysis on the potential prototype to ensure the investment could be repaid through offsetting future labour costs.”

The AGV project was chosen from a number of pitches by UK agri-tech businesses.

A requirement of the winning project was that it needed to be applicable to the wider horticulture industry and solve a problem relevant to many businesses. The overall goal is for the prototype to be developed commercially and is likely to cost around £30,000 to £50,000 depending on its configuration.

James Bean, Crystal Heart Salad Co. said, “WMG have made several visits to our nursery. They have carried out a study of our logistics and have identified a design of autonomous vehicle which can improve efficiency and remove low-skilled manual tasks.

“We are excited to see this move to the next stage, to conduct real-life tests of the technology. If it fulfils expectations, it will make a fundamental change to our business.”

Emeny added: “We know horticulture is at the forefront of a digital revolution in farming and our SmartHort programme is designed to help connect growers with automation and robotics experts to help accelerate innovation. This project demonstrates the potential opportunities available from matching skills outside horticulture to meet the needs of the industry.”