A £2.5 million indoor farm is set for construction near Dundee in a project to showcase vertical farming as a solution to food security.

Vertical farms, which produce food in vertically stacked layers using controlled environments, allow producers to grow crops quickly and with limited need for space, water or sunshine. They are already used in London, Singapore and New York, among other places.

Now Scotland will build a vertical farm of its own, using technology not seen before in the UK. The development of similar farms is expected to increase rapidly as LEDs fall in cost and efficiencies increase.

The James Hutton Institute and vertical farming entrepreneurs Intelligent Growth Solutions (IGS) have agreed on plans to establish the futuristic farming facility at the Institute’s site in Invergowrie near Dundee.

The James Hutton Institute’s chief executive Professor Colin Campbell said: “Vertical farming is an efficient way of growing plants on a small footprint in urban situations with low energy and water inputs.

“We are doing more research with such innovative companies in the private sector and this example combines our knowledge of plant science and specialised infrastructure to work with others whose vision is aligned to help solve the challenges around long-term food security.”

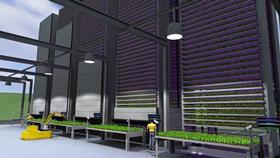

The purpose-built facility will be the first in the UK to house automated growth towers for vertical, indoor farming. Local councillors have already granted approval for the project, and a 10-year lease has been signed by the James Hutton Institute and IGS.

IGS predicts costs will fall quickly to allow crops such as strawberries and tomatoes to be added to the leafy salads and herbs currently grown indoors.

Henry Aykroyd, IGS CEO and an agri-entrepreneur with 30 years’ experience in large-scale farming in the UK, Eastern Europe and California, added: “Our mission is to enable our customers to be the lowest cost producers by growing local globally, with better quality and saving natural resources.

“The process uses little water, no pesticides, can enhance taste and is consistent all year round. Our real-time software can ‘grab’ power when the grid has surplus power and ‘shut down’ at peak times.

“Our automated growth towers are fully programmable to suit many diverse crops, and provide smart solutions to automation, power management and lighting issues.”