The A$2m research programme will use computer vision and machine learning to find an automation solution

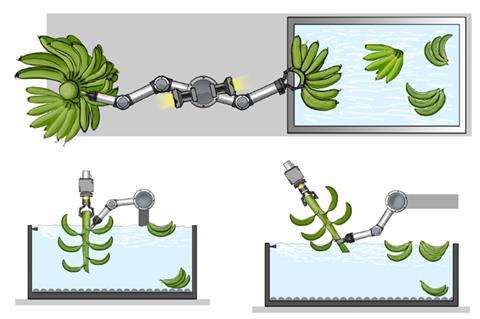

Australian scientists are researching and developing new technology to build a robotic arm that will automate the repetitive and intensive parts of banana processing.

The research will be delivered through Hort Innovation and led by the Queensland University of Technology (QUT) in collaboration with Future Food Systems, the Advanced Robotics for Manufacturing (ARM) Hub and BNL Industrial Solutions. The A$2m programme will use technology such as computer vision and machine learning to provide the banana industry with a solution for the process known as banana ‘de-handing’.

Banana de-handing is the process of separating the banana fruit from the stalk and it is a repetitive and physically demanding activity that, if automated, could improve processing efficiencies and provide a valuable integration point for robotics systems.

Hort Innovation chief executive Brett Fifield said investing in emerging technology to make production easier is a key priority.

“Workforce challenges, supply chain issues, and disease threats all contribute to the need to find innovative production approaches,” Fifield said.

“If successful, this type of technology could also be applied to other crop-types to support Aussie fruit and vegetable supply.”

QUT lead researcher Chris Lehnert said commercialisation is the goal.

“Over the next two years we will build the prototype robot for banana de-handing and then integrate that robot with a vision system that allows it to ‘see’ what actions it needs to perform,” Lehnert said.

“The prototype will then be trialled at the ARM Hub’s testing facility where we will conduct further testing and allow growers and potential investors to come and see it action.”

Australian Banana Growers’ Council chief executive Leanne Erakovic said the banana industry was keeping a close eye on the project.

“Currently there is no commercially-available solution for the banana industry,” Erakovic said.

“Banana de-handing is a core process in all banana packing sheds, so any efficiencies that could be realised through the use of robotic technology would likely have a significant impact on growers’ processing costs. A win-win for our industry and for consumers.