The non-invasive sensor team from Queensland’s CQUniversity has delivered new tools to accurately assess the ripeness of mango crops prior to harvest and retail, a development which could improve mango operations around the world.

The sensor system technology uses near infrared spectroscopy (NIRS) to assess produce in the orchard without damaging the product. As a result, growers can test mangoes for maturity without having to rely on visual cues or cutting the fruit open.

In some cases, farm performance has increased by more than 40 per cent according to developers, because early and accurate assessment of the ripeness of fruit has bolstered crop productivity through optimised harvest timing and improved fruit quality.

Ian Groves of Groves Grown Tropical Fruit said a big variation between varieties or just a lack of cues in some varieties meant he often had to look at the flesh colour to determine if the mangoes were ripe. That has now changed.

“With one of the NIRS guns we are now able to walk through the orchard testing fruit, seeing if there’s enough to go through a spot pick or whether they’re all ready and train up our workers as to the visual cues as to what a mature mango looks like,” Groves said.

“It just means we can get our start date correct so that we're picking fully mature fruit that the customer is going to be happy with.”

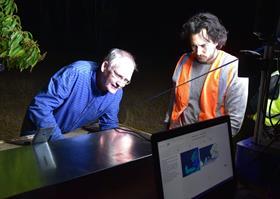

CQUniversity professor Kerry Walsh, who lead the team, said they were originally prompted by growers to estimate the quality of the fruit on the packing line non-invasively, but watching the growers prepare for harvest in the orchard led them to look at machine vision in the orchard.

The next step will be integrating this technology with other machinery and automation according to Walsh. “It’s actually getting more advanced and so now the machinery is able to identify and count fruit in the orchard.”

“Knowing how much fruit is in the block, knowing when it’s going to be mature, knowing the size of the fruit means we can schedule our workforce,” Walsh said.

“We can order the right number of cartons, we can order the right numbers of inserts to go in those cartons. This could be a real game-changer for not only our farm, but for the industry.'

The non-invasive sensor team is now investigating robotic harvesting techniques and the use of machine vision for assessing mango flowering and fruiting.

It has already made some progress with the former, with a successful field trial of the first prototype of its mango auto-harvester.