Infarm, the world’s fastest-growing urban farming company already available in 10 countries and 30 cities in thousands of stores, continued the rollout of its vision for a global interconnected, sustainable and highly efficient farming ecosystem.

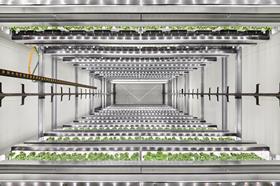

As part of its goal to drive innovation within the US$3 trillion global fruit and vegetable market, Infarm today introduced its new high-capacity, automated, modular Growing Center - a local farm and distribution centre in one, that can generate the crop-equivalent of up to 10,000 m2 of farmland, with up to 400 times higher efficient food production than soil-based agriculture.

The cloud-connected, high-yield growing centres join Infarm’s expanding global network of self-learning farms that improve plant yield, taste, and nutritional value constantly, while further reducing the use of natural resources. With 50,000 m2 of farming facilities and hundreds of farms in stores locations, Infarm is already providing fresh produce to 50 per cent of the world’s largest food retailers. The rapid deployment capability of the new high-yield Growing Centers will drive additional global growth and scalability to match the needs of retailers of any size in any location, with the goal of growing the network to 500,000 m2 by 2025.

A Growing Center comprises dozens of modular farming units, each standing between 10 and 18 meters high, occupying a 25 m2 ground footprint and requiring just six weeks to build, yielding the crop-equivalent of 10,000 m2 of farmland. This modular, data-driven, and distributed approach — a combination of big data, IoT, and cloud analytics, in addition to rapid growth at a global scale — sets Infarm apart from any other farming solution.

“Access to fresh, local and sustainable food is a growing challenge, as people shift towards cities and climate change accelerates, explains Erez Galonska, co-founder and CEO of Infarm. “Today we’re adding speed to scale with new technology that allows us to deploy a Growing Center to any city in the world in a fraction of the time, space and capital investment of most large-scale farming solutions today. Both the farms and the software that powers them were designed to make fresh food more accessible for everyone, everywhere.”

Many of the world’s leading food retailers are already taking part in Infarm’s farming network, including Empire Company Ltd (Safeway, Sobeys, ThriftyFoods), Whole Foods Markets, Marks & Spencer, Kroger, Kinokuniya, Aldi, Amazon, Auchan, Casino, E.Leclerc, Edeka, Intermarché, Irma, Kaufland, Metro, Migros, Selgros, Summit and in Germany, Canada, Denmark, France, Japan, Luxembourg, the Netherlands, the United Kingdom, the United States and Switzerland.

“The entire Infarm network is connected to a central farming brain that gathers more than 50,000 growth, color and spectral data points through a plant’s lifetime” explains Guy Galonska, co-founder and Chief Technology Officer at Infarm. “We've collected more than 300 billion data points throughout our farming network to date. These data enable us to perfect our growing recipes and improve yield, quality and nutritional value, while reducing the production price constantly.”

The large-scale Infarm Growing Centers integrate farming units that can each save up to 10,000,000 litres of water per year, compared to soil-based agriculture for similar crops, while contributing up to 40 per cent energy savings over previous Infarm technologies.

By 2025, Infarm plans to establish 100 Growing Centers - equivalent to 1.5 million m2 of farmland and producing 450,000,000 plants across its network, including expanding to new markets. This year, 15 Infarm Growing Centers are already planned/or under construction in major urban centers, including London, Paris, Copenhagen, Toronto, Vancouver, Seattle and Tokyo.

Additional features of the new Infarm technology:

• An automated mechanical farming system that is cloud controlled;

• Environmental settings like CO2, temperature, light, pH and growth cycles can be set, monitored, analyzed online across all farms;

• Recirculates 20 liters of water condensation per hour and, saving more than up to 10,000,000 liters of water per year compared to soil-based agriculture for similar crops;

• Smart LED management supports energy efficiency offering contributes up to 40% energy savings & up to 25% savings on initial investment.

Infarm says it uses 95 per cent less water, 90 per cent less transport and zero chemical pesticide than soil-based agriculture with the majority of electricity use throughout the Infarm network coming from renewable energy. To date, the Infarm network has saved more than 40,000,000 litres of water and 50,000 square meters of land.

Infarm was founded in Berlin in 2013 by Osnat Michaeli and brothers Erez and Guy Galonska.