Costa Group utilises live data to ensure its mushroom operations maintain quality and safety standards.

Costa Group’s mushroom operation Costa Mushrooms has harnessed the power of live supply chain data from Escavox to satisfy the cold chain specifications of the company’s supermarket customers and maintain trust with consumers.

The globally recognised fresh produce supplier, which accounts for about 50 per cent of Australia’s commercially grown mushrooms, supplies all major supermarket chains and central wholesale markets nationally from three sites – Mernda in Victoria, Monarto in South Australia and Casuarina in Western Australia.

Escavox, which also tracks other Costa categories such as avocados, bananas and grapes, supplies smart tracking technology to Mernda and Monarto to protect mushroom loads that are travelling short and long distances, particularly those to interstate locations over thousands of kilometres with more crossdocking points via road and (in the case of Tasmania) sea transport.

Costa’s Mernda-based quality assurance officer, Marietta Chua, said summer is a critical time for the company’s mushroom operation.

“The higher the ambient temperature, the more challenging it is to get the temperature control right and to ensure we have our mushrooms arriving in the same environment as they leave our load-out bay,” said Chua.

According to Chua, mushrooms are a temperature-sensitive food highly susceptible to damage if not stored and transported within a narrow temperature band from 1-4 degrees Celsius. She said there is no room for complacency or error in the harvesting, storing and transportation of mushrooms, as a result.

At the Mernda facility near Melbourne, about 250 tonnes of mushrooms leave on trucks every week.

Before they are despatched, they are stored after harvest in secure, highly controlled cold storage areas and regularly temperature probed until loaded onto refrigerated trucks, with each carton labelled and its data logged to provide full traceability.

Once inside the truck, Escavox smart trackers are allocated within the stacked cartons at a ratio of one to each load, to provide another layer of assurance, reading every 15 minutes the conditions to which the mushrooms are exposed.

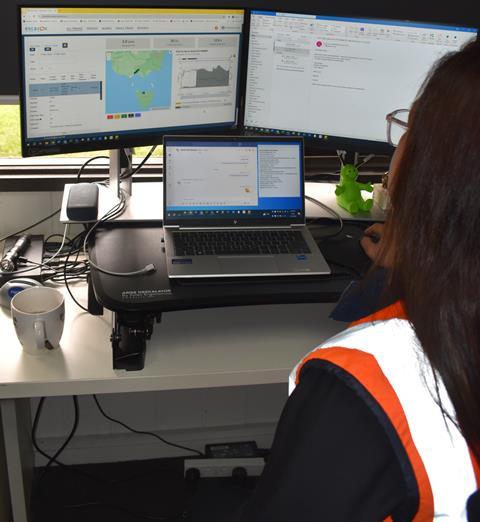

The information relating to location, temperature, light, humidity and movement is relayed to the Escavox MyTracks dashboard, an integrated, easy-to-read software platform exclusive to Escavox, which allows Chua and other quality assurance officers at Costa to see the mushrooms’ journey unfold in real time.

“We are looking at the Escavox data every day,” Chua said. “The information has become indispensable to our business.”

At Monarto in South Australia, every load of mushrooms leaving the farm has an Escavox tracker on board due to the vast distances their produce will travel.

At Mernda, loads destined for one major supermarket retailer have an Escavox tracker on board.

“We first started using Escavox because the compliance teams at the supermarket’s distribution centres were finding fault with our mushrooms’ temperatures, which in our assessment was at odds with the processes that we and our transport carriers were implementing,” Chua said.

“But we had no way of proving it. So, we adopted Escavox to provide a verifiable trace of the journey from farm to DC.

“Thanks to Escavox, the next time they advised our mushrooms would be rejected for being out of temp, we were able to prove temperature stability in the desired range and have the assessment reclassified to amber, allowing for the mushrooms to be sold.”

Chua said the information provided by Escavox can be used to gain additional benefits beyond the dollar and food waste savings, this include further refining cold chain management.

“Because we’re actively engaging with the data, we’re using it to continuously improve and upgrade our operations, ” Chua said.

“For example, we used to despatch at 4 degrees, but now it’s more like 3, and that’s because the data tells us that we’re more likely to hit the cold chain spec and get more shelf-life if we transport at the lower number.

“The data also helps us to work with our carriers and DC managers so that we all improve together.

“Since taking on board Escavox, we’re having far more data-informed conversations about what we do well, but more importantly, what we can do better.”