Packing soft fruits such as raspberries, strawberries, and blackberries is a daily balancing act. These products are valuable yet fragile, and getting them from field to customer in perfect condition becomes a big task. From labour shortages to costly overpacking and ever-tighter deadlines, the sector faces persistent obstacles. Fortunately, innovative solutions from Milbor PMC are changing the way fruit pack houses operate – making the process more efficient, accurate, and profitable.

Three key challenges in soft fruit packaging

Talking to our clients, we detected the main problems they are struggling with daily. The most reoccurring issues include:

- Labour shortages and workforce efficiency

Soft fruit packing requires human hands. Fruits must be sorted and packed with care to avoid damage, which makes automation more difficult than in other sectors. The challenge? Finding enough people to do the work. The jobs are repetitive, often in cold storage environments, and turnover is high. Even with higher wages, recruitment and retention remain difficult, and inconsistent performance reduces overall productivity.

- Overpacking and financial losses

A few grams of extra raspberries in every punnet may not seem like much, but across a season it can drain tens of thousands of euros from a pack house’s bottom line. Overweight punnets are a hidden cost that can easily reach €70,000 per season. On the other hand, underweight punnets risk complaints, returns, or penalties from retailers. Achieving pinpoint accuracy is essential.

- Pressure from last-minute orders

Retail chains and large buyers often place orders late, leaving little time for preparation. For packhouses with rigid lines and slow changeovers, this can mean frantic shifts, errors, and missed deadlines. Declining such orders risks losing valuable business, but meeting them with inefficient systems creates stress and costs.

Milbor PMC’s answer: precision, flexibility and control

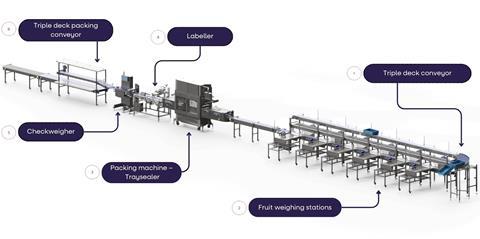

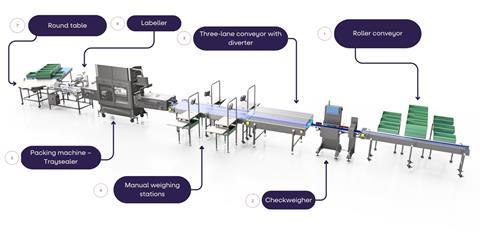

With over 13 years of experience in the fruit packing industry, Milbor PMC has developed tools and soft fruit packing lines that address these pain points directly. Our approach combines smart hardware: manual and dynamic packing lines – with intelligent software, the Libra system – to create smoother, faster, and more accurate operations.

Manual weighing lines and dynamic weighing lines

Manual weighing lines are ideal for fruits that require sorting or come on the vine. Each punnet passes through weighing stations equipped with precise scales, where operators can quickly adjust the content. The system is flexible and modular, so businesses can design it to fit their space and needs.

Dynamic weighing lines (semi-automatic) are built for products requiring less sorting. Using a checkweigher and a three-lane conveyor with diverter, the line automatically directs underweight, overweight, and correctly filled punnets to different paths. Operators then only perform targeted corrections. Compact and efficient, these lines optimise throughput even in limited spaces.

Both systems deliver measurable results:

- Up to 30 per cent higher productivity – fewer workers can achieve the same output

- Increased weighing accuracy – less waste, fewer complaints, and more profit

- Improved ergonomics – happier, more motivated staff who stay longer

- Flexible design – lines tailored to each packhouse’s requirements

- Durable build quality and reliable service – reducing downtime and disruptions.

Libra software – the digital backbone

The Libra software is an optional addition for both manual and dynamic weighing lines. It monitors individual worker performance, tracks jobs in real time, and provides managers with instant reports. The software also speeds up line changeovers, reduces paperwork, and supports smarter staff allocation. In practice, this means:

- Faster reaction to last-minute orders

- Clear visibility of who performs best on the line

- Automatic error reduction thanks to integrated weighing and signalling systems

Contact us and turn challenges into opportunities

The problems of soft fruit packing aren’t going away – but with the right systems, they can be transformed into competitive advantages. More efficient and motivated staff, fewer losses from overweight punnets, and the ability to say “yes” to urgent retail orders all add up to stronger margins and a more resilient business model.

Milbor PMC offers a tailored path forward higher efficiency and profitability in soft fruit packing business. With expert consultation, we will help determine whether a manual or dynamic weighing line is right for your business and provide ROI calculations to guide the investment.

Eager for more? Contact Maciej and find out more about Milbor PMC’s soft fruit packing solutions.

Maciej Chmielewski

Milbor PMC

Tel: +48 538 359 172

Email: m.chmielewski@milbor.pl

www.milborpmc.com