The Polish packing and sorting specialist has the solutions to cater for the evolving needs of the berry business, says chief executive Piotr Milewski

What innovations have you been working on in the past year?

Piotr Milewski: Most of our focus is on how to create more value from existing equipment and improve our customers’ efficiency. A lot of loss is due to the lack of proper production data and inefficient use of machinery.

We try to solve these problems by integrating machines that improve the average line efficiency. An example is a tandem labeller – one that doesn’t need production to stop for label changeover. With this relatively small upgrade we see an increase of overall capacity by 6 per cent.

We are also introducing software and automation solutions that collect data from production lines and offers insight to the line managers.

How positive is the market for your products?

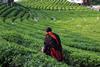

PM: The global market for our products is currently promising, especially due to the rising consumption and supply of blueberries worldwide.

New players are welcomed on the market, however they need to align with the requirements of retail networks and consumers. Meeting these demands necessitates having the right production infrastructure as well as reliable equipment and a high-quality service.

Our services align seamlessly with today’s market demands.

What trends do you see in the berry business?

PM: One significant trend in the berry business is the growing consumer awareness of and their preference for retail chains offering fresh and high-quality berries. Our solutions are tailored to ensure that these conditions are met, enabling retail chains to provide top-notch berries to their customers.

How have you coped with the challenges facing the industry?

PM: The year has been quite positive for our company. We have effectively managed potential challenges – our solutions and years of experience have helped our clients in cost optimisation. This has allowed all of us to navigate the rising costs and face global economics successfully.

What new developments have there been in terms of new markets or customers?

PM: We have been operating successfully in the Polish, German, Benelux, UK, and Moroccan markets. Additionally, we are expanding our presence in the Spanish market and initiating an exciting venture in Romania and Serbia.

These new markets were targeted as part of our ongoing growth strategy to diversify our geographic footprint and tap into emerging opportunities within those regions.

What do you anticipate the next 12 months will bring?

PM: Our hopes for 2024 are to enhance our existing solutions and continue to automate more areas of the soft fruit packing and sorting process.

We see that labour cost and availability will remain a top challenge for our customers and we want to support them with state-of-the art automation solutions.