The 17,500 sq m facility integrates processing, coldstorage and container depot operations in northern Peru’s agricultural corridor, with capacity to handle over 10,000 tonnes of produce in its first year.

Logistics giant Maersk has officially opened a new packing and cold chain logistics centre in Olmos, Peru, a strategic move it says will support the country’s booming agro-export sector as its fresh fruit exports continue to rise.

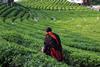

Strategically positioned in the heart of northern Peru’s agricultural corridor, the Olmos site is a newly developed, multi-product fruit logistics centre designed to streamline the region’s export capabilities and, as Maersk puts it, deliver speed and freshness from farm to port.

Located in Lambayeque, Olmos has rapidly become one of Peru’s most dynamic agricultural zones. According to Peru’s National Institute of Statistics and Informatics, the region’s fruit exports grew significantly in 2024, including a 35.7 per cent increase in blueberry exports and a 29.2 per cent rise in avocado exports.

The new facility is close to major plantations and integrates essential logistics functions including processing, coldstorage, and depot warehousing that connect to Maersk’s global supply chain network.

It also offers value-added services, such as container depot operations, inland refrigerated transport, and customs handling at origin, which the company says ensure a seamless end-to-end experience for its customers.

“This Olmos Packing and Cold Storage Centre represents far more than a logistics investment, it’s a strategic commitment to the long-term growth of northern Peru’s agro-export sector,” says Dean Rodin, managing director for the West Coast of South America at Maersk.

“By establishing operations in Olmos, we’re empowering local producers to compete on a global scale with the speed and quality that today’s markets demand. Our decision was guided by the region’s exceptional export performance, its proximity to key plantations, and the clear need for integrated cold chain infrastructure to unlock its full potential.”

Northern exposure

According to Maersk, the 17,500 sq m facility is the first of its kind in northern Peru, and has been engineered to manage the complete post-harvest journey for three primary fruit types – avocados, blueberries, and mangoes. Additionally, it says, the centre can support other seasonal exports by serving as a coldstorage solution for packaged products, for example grapes.

Over 10,000 tonnes of produce are expected to pass through its doors during the first year.

The facility also offers:

- Processing: Up to 38 tonnes/hour for avocados and mangoes; 4.5 tonnes/hour for blueberries.

- Storage: Over 4,600 bins across climate-controlled and refrigerated rooms, as well as two chambers for finished goods storage with 2,088 pallet positions.

- Cooling: Seven rapid cooling tunnels with 18 positions each to ensure preservation. The facility is equipped with specialised precooling systems designed specifically for blueberries, a critical step in post-harvest handling that helps rapidly reduce field heat, extend shelf life, and preserve fruit quality during transport.

- Logistics: Five loading docks and an on-site integrated depot with 420 container slots and 210 plug-in points.

- Technology: Automated packing lines, calibration, electronic sorting, Warehouse Management System, and Enterprise Resource Planning systems for customer visibility, efficient inventory and packaging management.

- Decarbonisation: In line with Maersk’s 2040 targets, the new facility features electrified equipment and an on-site water treatment system. In 2026, solar panels will be installed to further reduce the facility’s environmental footprint and support renewable energy use.

“We designed this facility to meet the highest international standards in cold chain logistics,” says Juan Eduardo Ritz, regional head of cold chain storage for Maersk Contract Logistics in Latin America. “From automation to food safety, every detail supports our mission to reduce waste, extend shelf-life, and deliver quality produce to global markets.”

He adds: “Cold chain integration plays a critical role in this process: it ensures food safety, maintains quality assurance, and significantly shortens the time from harvest to cold stabilisation. With the advanced systems in place here in Olmos, we’re able to minimise fruit loss and damage by at least 10 per cent, helping our customers protect both product value and reputation.”